I just wanted to give a big thank you to Vibest International for a wonderful product. I have had my greenhouse for over three years, and have managed to consistently grow a lot of plants with great success. Especially during the construction of my greenhouse, the sales and technical support teams at Vibest has been outstanding

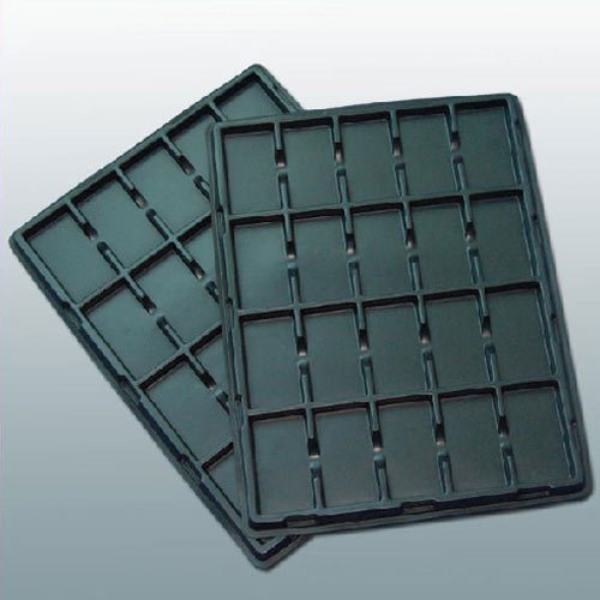

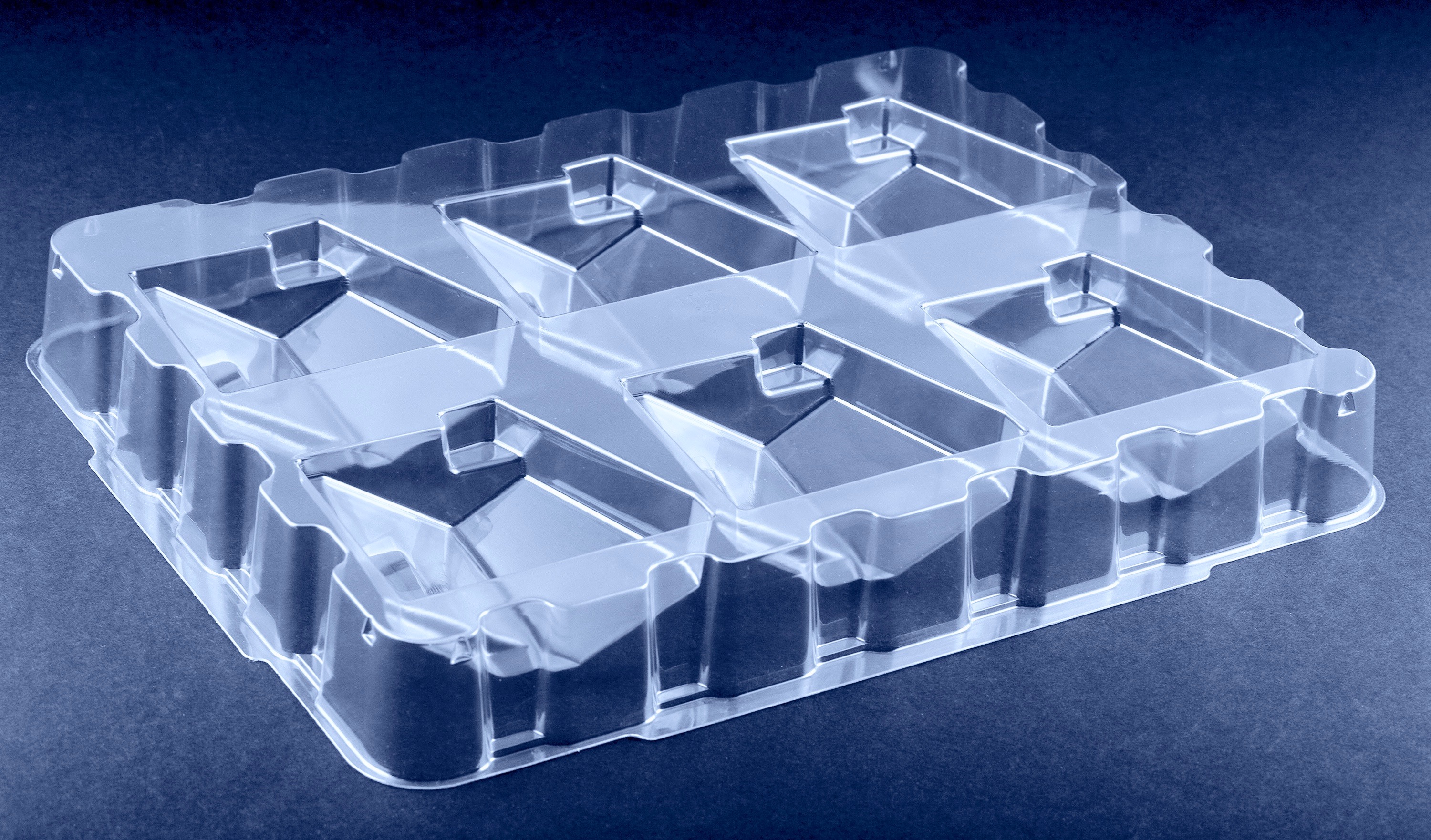

The thermoforming process requires a few pieces of equipment. The forming process needs either pressure formers or vacuum formers. It also requires a three or four-station Rotary Transformer. The secondary operation of the process needs CNC robotic routers. Normally the bed for this piece of equipment does not exceed 60”X 120”. The tooling process requires machine aluminum molds, cast aluminum molds, composite or temporary molds, or male/female molds.

1.jpg)